PCC

It treats exhaust gases before they reach the main catalytic converter, starting the conversion of harmful pollutants like hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx) into less harmful substances.

Agriculture

Marine

I.P.P

Mining

Aviation

Logistics

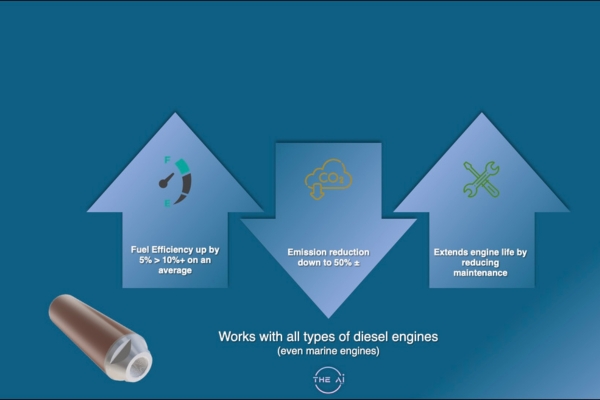

Sustainability & Operational Efficiency

- Emissions were tested at the exhaust outlet

- After Market solution.

- Explosion proof design

- No engine modifications required

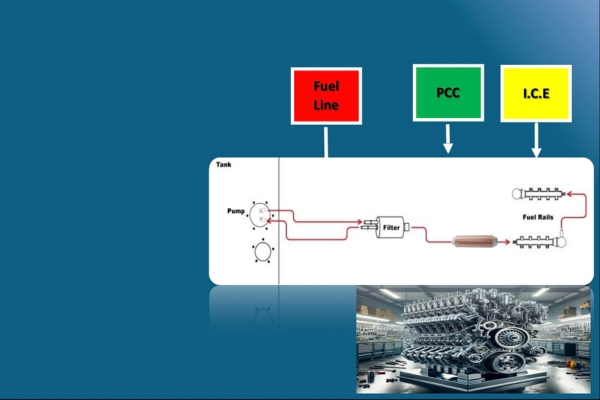

- Installed between external fuel line

- Install and forget solution

- Product warranty up to 10 years

Workflow

- A 360 degree approach to Green House Gas reduction

- Bypassing liquid fuel through the fuel regenerator, you can utilize up to 70%+ more energy.

- Our passive catalyst elements helps in fuel optimization by changing the hydrocarbon chain.

- Creates better fuel efficiency & reduce GHG emissions while creating a more sustainable fuel use

How it works?

- The Fuel Regenerator, also known as the ‘Onboard Mini Refinery’, is a revolutionary technology that uses a facilitator made of Heterogeneous Metallic Alloy Composition (HMAC).

- It cracks aromatic hydrocarbon molecules, resulting in better fuel quality, up to 25% fuel savings, reduced carbon footprint and lowered emissions.

- The facilitator has an average return on investment of (I.R.O.I) 12 – 15 months or less.*